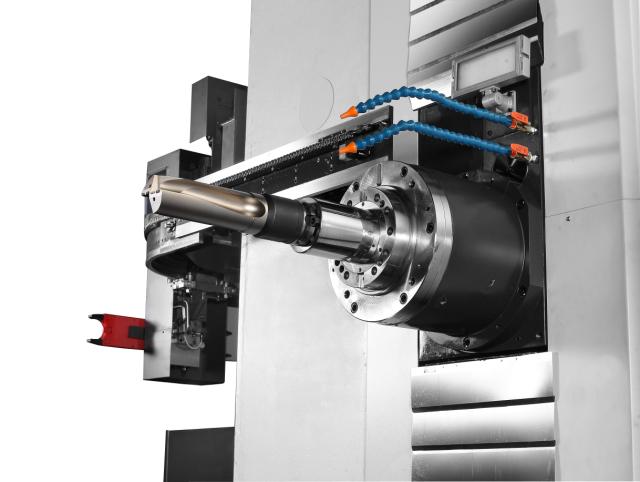

DBC Series

HORIZONTAL BORING MACHINE

- Advanced Technical Capabilities: Designed to handle a wide range of parts from mid to large sizes, including die and mold components.

- Enhanced Productivity: Improved design features boost operational efficiency and productivity.

- User-Friendly Operation: Enhanced operating convenience ensures ease of use and increased efficiency for users.

Highlights

- Travels - X Axis Travel distance (mm): 2000

- Travels - Y Axis Travel distance (mm): 1500

- Travels - Z Axis Travel distance (mm): 1200

Compatible Control System

Fanuc

Series description

|

The DBC series, ranging from compact to super-size models, meets diverse customer needs with advanced technical capabilities. Designed for processing mid to large-size parts, including die and mold components, the series enhances productivity and adds value through improved design, operating convenience, and efficiency. |

Specifications

Travels

| Travels - X Axis Travel distance (mm) | 2000 |

|---|---|

| Travels - Y Axis Travel distance (mm) | 1500 |

| Travels - Z Axis Travel distance (mm) | 1200 |

| Travels - Z Axis Rapid Traverse (m/min) | 12 |

Feed rates

| Feed rate - X Axis Rapid Traverse | 12 |

|---|---|

| Feed rate - Y Axis Rapid Traverse | 12 |

Table

| Table Length (mm) | 1600 |

|---|---|

| Table Width (mm) | 1400 |

| Max. Workpiece weight (kg) | 7000 |

Workpiece capacity

| Max. Workpiece Diameter (mm) | 2100 |

|---|---|

| Max. Workpiece weight (kg) | 7000 |

Tool storage capacity

| Machining center - No. of tool station | 40/60/90 |

|---|

Main spindle

| Main Spindle Max. Speed | 3000 |

|---|---|

| Main Spindle Max. Power | 26 |

| Main Spindle Max. Torque | 1104 |

| Tool Taper (ISO) |

Turret

| Turret - No. of tool station | 40/60/90 |

|---|

Dimensions

| Length (mm) | 5540 |

|---|---|

| Height (mm) | 4200 |

| Width (mm) | 5920 |

| Weight (kg) | 29000 |

| Name | Download | File type | |

|---|---|---|---|

|

DBC series.pdf | 6915 KB |

Series delivery and installation

|

The project team manages the entire process, including delivery, installation, and commissioning of the machine, ensuring a seamless project flow. The project team ensures coordination and communication between the project's parties, including the customer, Duroc Machine Tool, and any third-party subcontractors. |