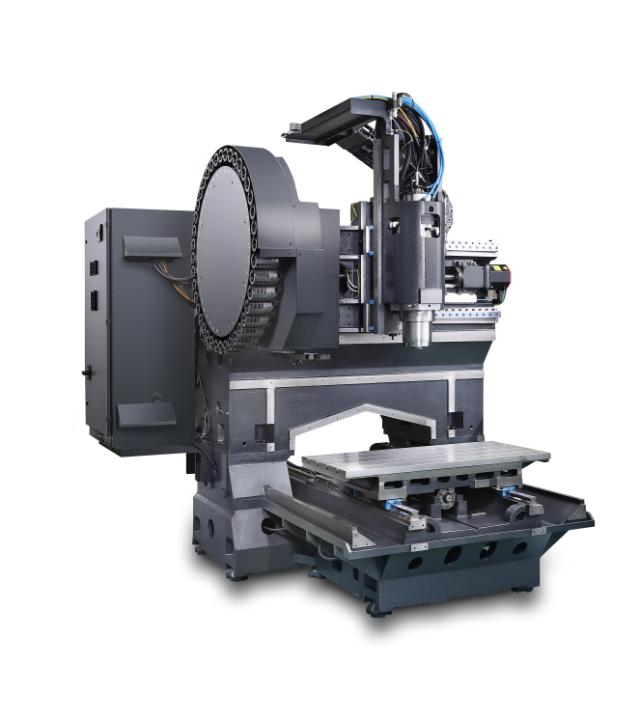

BVM 5700

HIGH SPEED, HIGH PRECISION PREMIUM VERTICAL MACHINING CENTER

- Optimized Stability and Accuracy: Bridge frame structure ensures precise and stable machining.

- High-Speed Machining: 15,000 rpm built-in spindle delivers exceptional speed for efficient operations.

- Top Precision and Productivity: Ideal for customers demanding the highest levels of precision and productivity.

Highlights

- Travels - X Axis Travel distance (mm): 1050

- Travels - Y Axis Travel distance (mm): 570

- Travels - Z Axis Travel distance (mm): 460

Series description

|

The BVM 5700 vertical machining center features a bridge frame structure for optimized stability and accuracy. Its 15,000 rpm built-in spindle enables high-speed machining, making it an excellent choice for customers seeking top precision and productivity. |

Specifications

Travels

| Travels - X Axis Travel distance (mm) | 1050 |

|---|---|

| Travels - Y Axis Travel distance (mm) | 570 |

| Travels - Z Axis Travel distance (mm) | 460 |

| Travels - Z Axis Rapid Traverse (m/min) | 36 |

Feed rates

| Feed rate - X Axis Rapid Traverse | 42 |

|---|---|

| Feed rate - Y Axis Rapid Traverse | 42 |

| Feed rate - Z Axis Rapid Traverse | 36 |

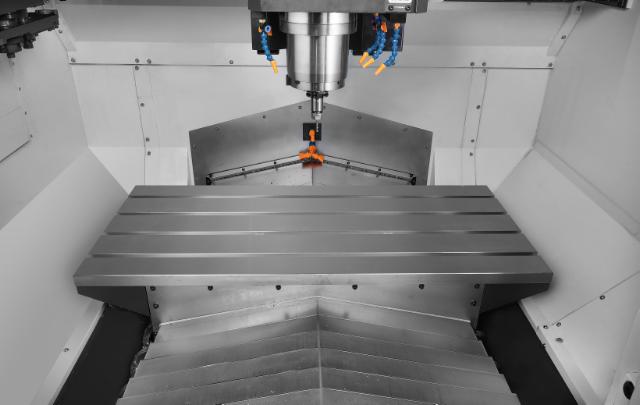

Table

| Table Length (mm) | 1300 |

|---|---|

| Table Width (mm) | 570 |

| Max. Workpiece weight (kg) | 1000 |

| Max. Table weight (kg) | 1000 |

Workpiece capacity

| Max. Workpiece Height (mm) | 495 |

|---|---|

| Max. Workpiece weight (kg) | 1000 |

Tool storage capacity

| Machining center - No. of tool station | 30/40 |

|---|

Capacity

| Table to spindle nose | 610 |

|---|

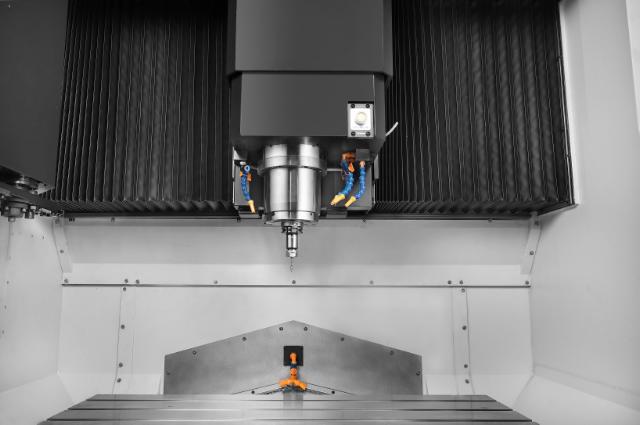

Main spindle

| Main Spindle Max. Speed | 15000 |

|---|---|

| Main Spindle Max. Power | 37 |

| Main Spindle Max. Torque | 214 |

| Tool Taper (ISO) | 40 |

Turret

| Turret - No. of tool station | 30 |

|---|

Dimensions

| Length (mm) | 3080 |

|---|---|

| Height (mm) | 2890 |

| Width (mm) | 2560 |

| Weight (kg) | 7500 |

| Name | Download | File type | |

|---|---|---|---|

|

BVM 5700.pdf | 4285 KB |

Series delivery and installation

|

The project team manages the entire process, including delivery, installation, and commissioning of the machine, ensuring a seamless project flow. The project team ensures coordination and communication between the project's parties, including the customer, Duroc Machine Tool, and any third-party subcontractors. |